Craftsmanship

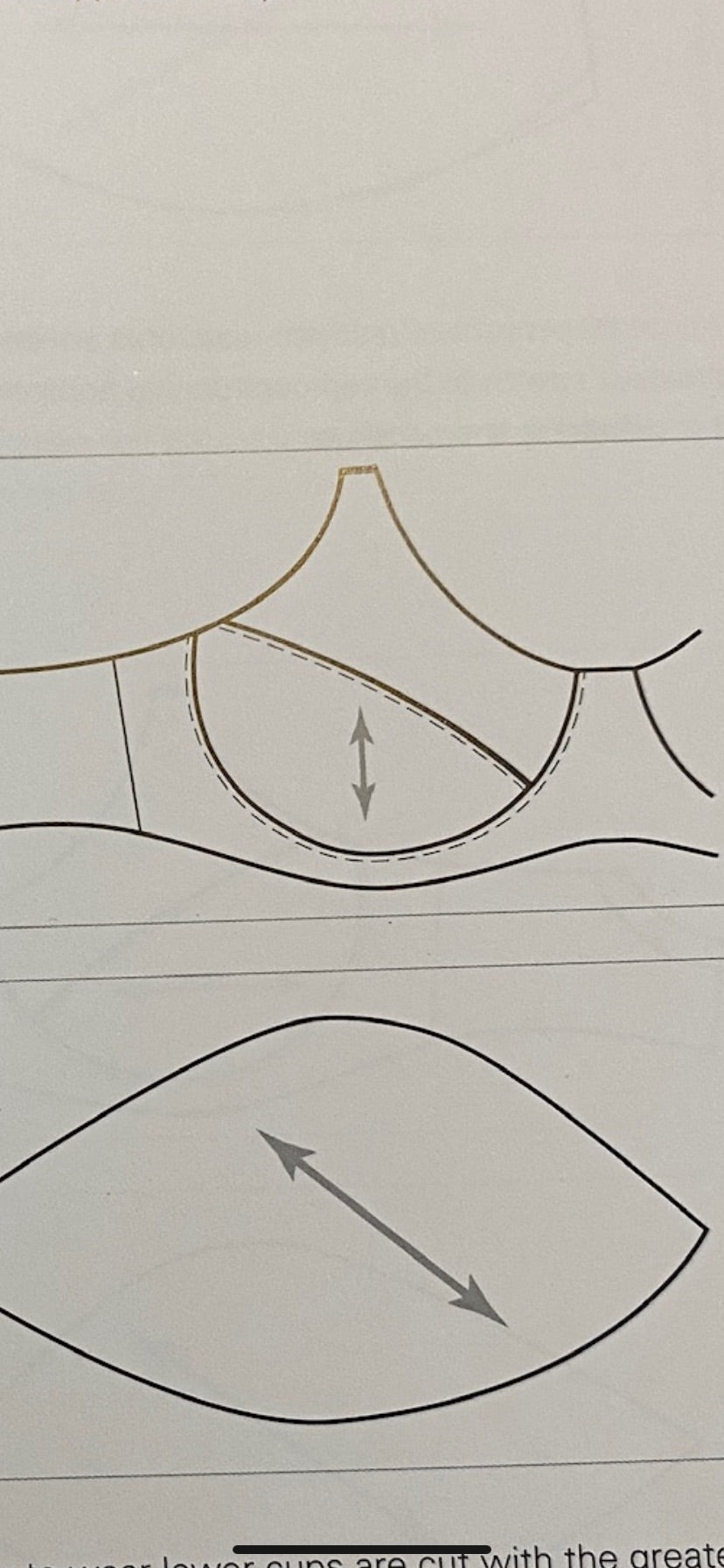

At the heart of our lingerie lies a dedication to both craftsmanship and sustainability. Each piece is meticulously crafted through a series of steps that require extensive training and experience, from designing and pattern-making to sewing and finishing. Our skilled artisans bring these elements to life with precision and care, ensuring that every item meets the highest standards of quality and durability.

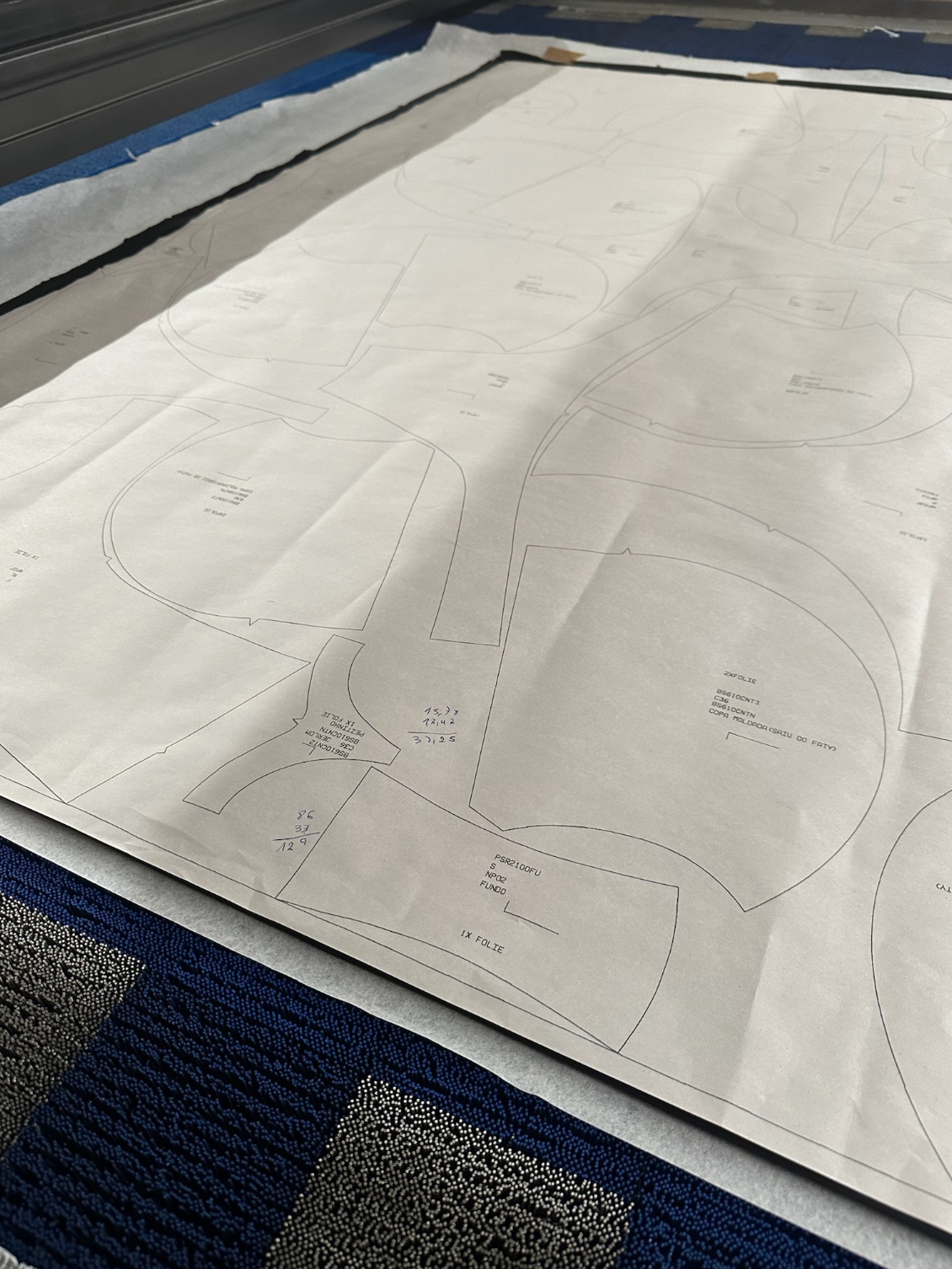

Innovative Techniques for Precision and Waste Reduction

To enhance both the quality and sustainability of our products, we employ advanced technologies such as laser cutting and digital pattern-making. Laser cutting allows us to create intricate designs with minimal material waste, while digital pattern-making streamlines the design process, reducing errors and further minimizing waste.

Sustainable Materials and Practices

We are committed to using more sustainable materials wherever possible. This includes incorporating some recycled fabrics into our designs and using recycled plastic for our packaging. For the first edition we have used a 100% recycled deadstock fabric for our Secret Garden styles and chosen OEKO-TEX, Global Recycled Standard and Better Cotton for our Gwyneth and Soft kiss styles. However, we recognize that sustainability is a journey, and we are continuously exploring new ways to reduce our environmental impact.

One challenge we face is the use of elastane, which is necessary for stretch and fit but complicates the recycling process. Currently, some of our designs still require 4-8% elastane for optimal fit. Our goal is to transition to bio-elastane enabling a fully circular model where old underwear can be recycled into new lingerie. Our fully recyclable styles are made from 100% cotton.

The Challenges of Sustainable Lingerie

Sustainability in the lingerie industry comes with its own set of challenges. The higher cost of sustainably sourced materials, such as organic cotton or ethically produced silk, as well as ensuring fair wages and responsible practices across the supply chain, leads to higher prices for consumers. We believe that sustainability is not just an option but a necessity, and we are committed to providing high-quality products that are worth the investment.

To further combat waste, we produce our lingerie in small batches, limiting production to around 50 units per style and per size based on customer demand. This approach helps us avoid overproduction and ensures that each piece is made with purpose.

By the end of 2026, we plan to donate 1% of our annual revenue to a women's lead non profit organization that empower women’s leadership to protect our environment.

Our Portuguese Manufacturer

A crucial part of our commitment to quality and sustainability is our choice of a European manufacturer based in Portugal. We specifically selected this manufacturer to ensure that we could maintain close oversight of the production process and personally verify that both quality standards and worker conditions are consistently met.

The wonderful team at our Portuguese factory is composed of highly skilled artisans, many of whom are women with decades of experience in lingerie craftsmanship. The two incredible women who lead our production team have been working there for over 25 years. Their expertise and passion for their craft are what make our designs and patterns come to life with such precision and artistry.

Choosing the right manufacturer was no easy task. Our dedication to using cotton - a material not commonly employed in lingerie production - presented a significant challenge. Finding a partner willing to take on this project was difficult, as it required a unique set of skills and additional expertise to handle the time-consuming tasks associated with our designs. We are incredibly fortunate to have found a team that not only accepted the challenge but excels at it, bringing a level of craftsmanship that is unmatched.

We are deeply involved in every step of the production process. We perform all quality controls ourselves and visit the factory several times a year to ensure our standards are upheld. We also collaborate closely with the team during fittings, trying on all sizes together to guarantee the perfect fit for our customers. This hands-on approach ensures that every piece we create is a testament to the skill, dedication, and care of everyone involved.

European Materials & Sourcing

We are committed to sourcing all of our materials exclusively from Europe, ensuring the highest quality and craftsmanship. This includes everything from thread and hooks to elastics and trims. We seek out suppliers with a rich heritage and deep expertise in their fields, such as Italian deadstock providers or French lace manufacturers who continue to produce on traditional machines.

Transparency is at the core of our values, and we carefully select materials that are either deadstock, recycled, or certified by OEKO-TEX, BCI, or GOTS. We hold our suppliers to rigorous standards to ensure that every component of our products aligns with our commitment to quality and sustainability.

A Transparent Journey Towards Improvement

We are committed to transparency in our practices and want to take you along on our journey towards greater sustainability. While there are complexities in sourcing materials like cotton, especially concerning labor practices and environmental impact, we are continually seeking to improve. Whether it’s through better sourcing, exploring alternatives to elastane, or investing in responsible fibers, we are dedicated to evolving and doing better.

We invite you to join us on this path, knowing that each purchase is a step towards a more sustainable future for fashion.